Reduce costs, improve efficiency.

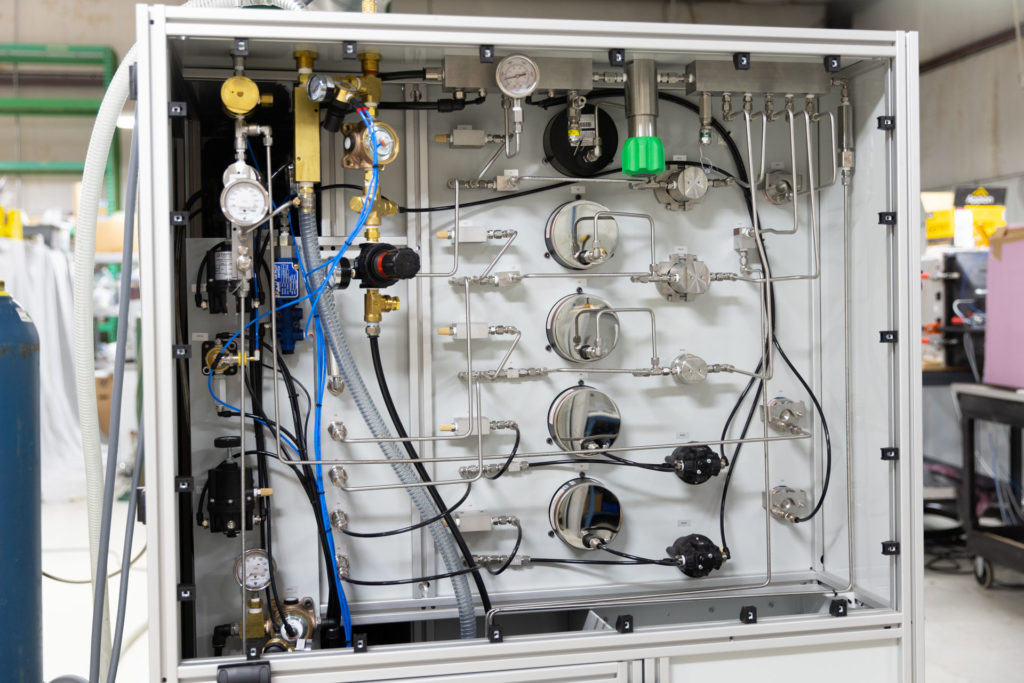

Utilized by prominent FAA repair stations and oxygen mask manufacturers, AMI’s Crew Mask Test System (CMTS II) product reduces labor requirements while enhancing testing efficiency and accuracy.

Whereas manual tests can take multiple hours, our latest-generation CMTS system uses an automated computer-controlled system to perform mask and regulator testing in less than one hour. Not only that, but each test is also performed to exacting test standards to ensure the long-term durability and functionality of each mask.

Product engineering

Differentiators

How AMI improves crew mask testing

Automated Testing

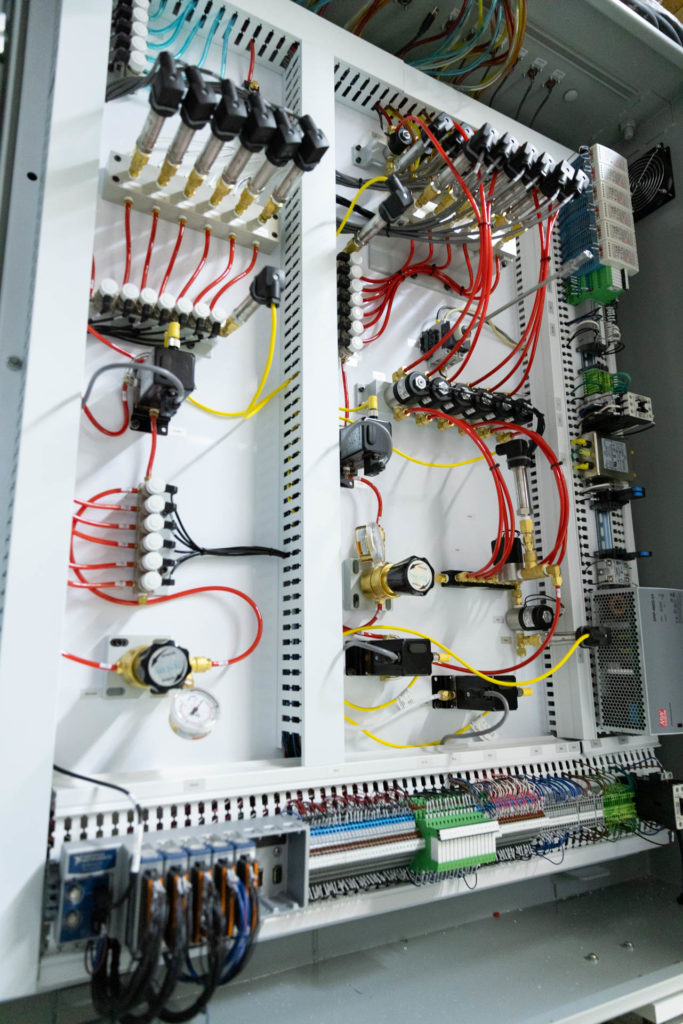

With automated testing from AMI, you can eliminate the need for making manual adjustments of flow controls and pressure regulators—while visually monitoring gauges and panel meters. Instead, our test system minimizes user interaction and greatly improves efficiency by automatically adjusting these various controls and monitoring sensors during testing.

Quality and Accuracy

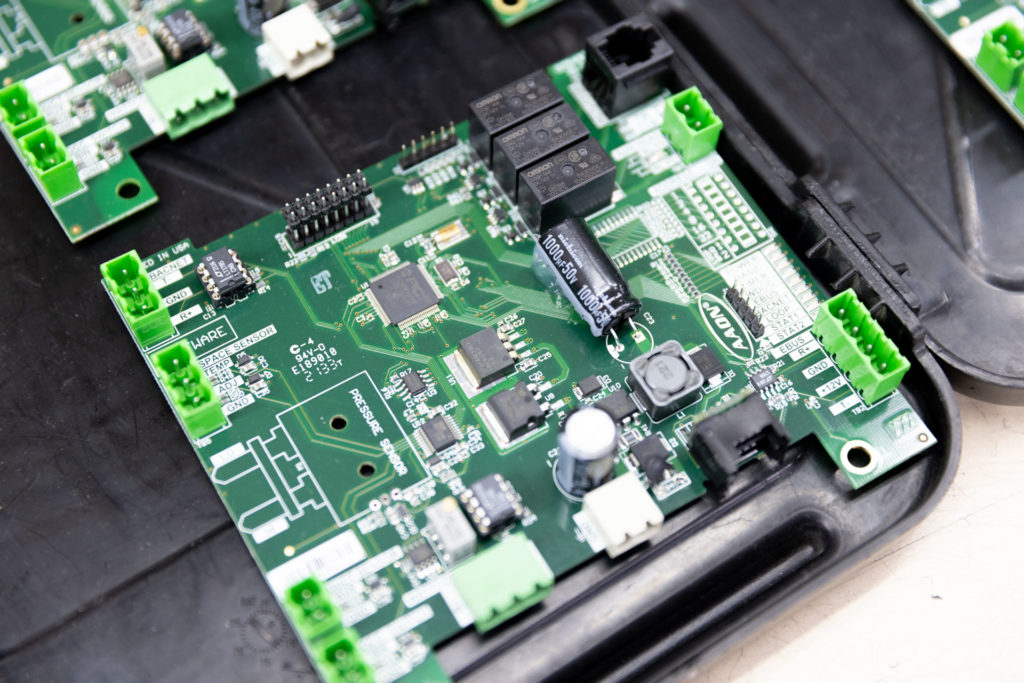

Enhanced efficiency doesn’t mean much if test results are not accurate. That’s why our Product Engineering team is dedicated to utilizing highly precise instrumentation to ensure the accuracy of the test results. This in addition to a rigorous quality assurance process yields the highest standards of quality.

Personalized Service

We completely personalize each test system we provide based on the needs of your company. If you need a certain feature or test performed for your crew mask testing, AMI can provide it.

Enhance productivity and profitability, whichever industry you're in.

AMI takes immense pride in providing high-quality, personalized service for businesses in the aerospace industry. Our team has provided solutions and met the needs of aerospace companies across the world. And we’re dedicated to enhancing your operations and exceeding your expectations.

Each service is performed by reliable employees and backed by proven processes, ensuring that we meet any deadline you set forth. Throughout your experience, industry veterans will answer all of your questions and work tirelessly to ensure your satisfaction.

Building effective solutions

Work with our team

With proven processes, decades of experience, and a dedication to quality, there’s no limit to what we can accomplish. Contact AMI today and put your project in the best hands possible.